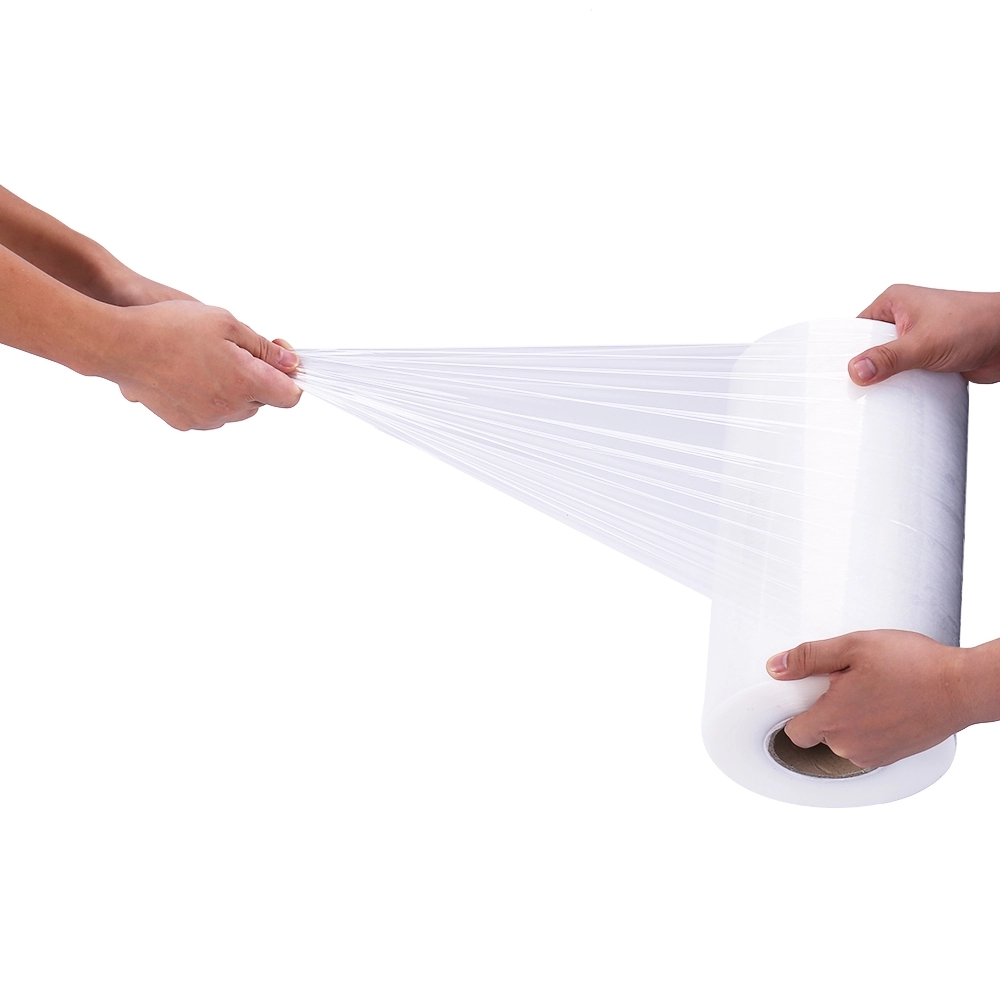

Polyethylene Film Material:

Some additional information: Polyethylene film are often used for shrink film or stretch film, counting on the shape . you'll got to know which form you would like for your product.

Manufacturers create polyethylene when adding ethylene to polyolefin during the polymerization process. There are three different sorts of Polyethylene: LDPE or Low-density Polyethylene, LLDPE or Linear Low-density Polyethylene, and HDPE or High-density polyethylene. They each have various applications, but normally, the LDPE form is employed for shrink film packaging.

Strengths:

Beneficial for wrapping multi-packs of heavy items—for example, an outsized count of beverages or water bottles. it's highly durable and is in a position to stretch quite other films. like polyolefin, polyethylene is FDA approved for food contact. While PVC and polyolefin films are limited in thickness, usually only up to 100-gauge, polyethylene are often scaled up to 1200-gauge, making it ideal for wrapping vehicles like boats for storage. Uses range from bulk or frozen foods to trash bags and palletizing as stretch wrapping. ask your manufacturer to understand which form (LDPE, LLDPE, HDPE) you ought to use.

Weaknesses:

Polyethylene features a low shrink rate of around 20% and isn’t as clear as other films. it's costlier than other films. Polyethylene shrinks while cooling after it's been heated, making it necessary to possess additional space for cooling at the top of your shrink tunnel.